The commonly used metal aluminum-based plates for aluminum substrates mainly include 1000 series, 5000 series and 6000 series. The basic characteristics of these three series of aluminum materials are as follows:

One. The 1000 series represents 1050, 1060, and 1070. The 1000 series aluminum plate is also called pure aluminum plate. Among all series, the 1000 series contains the most aluminum, and the purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is currently the most commonly used series in conventional industries. Most of the products circulating on the market are 1050 and 1060 series. The 1000 series aluminum plate is based on the last two digits to determine the minimum aluminum content of this series. For example, the last two digits of the 1050 series are 50. According to the international brand naming principle, its aluminum content must reach 99.5% or more to be a qualified product. In my country's aluminum alloy technical standard (GB/T3880-2006), it also clearly stipulates that the aluminum content of 1050 reaches 99.5%. For the same reason, the aluminum content of 1060 series aluminum plates must reach 99.6% or more.

Two. 5000 series represents 5052, 5005, 5083, 5A05 series. The 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%, which is also called aluminum-magnesium alloy. The main features are low density, high tensile strength, and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than that of other series, so it is often used in aviation, such as aircraft fuel tanks. In addition, it is widely used in conventional industries. Its processing technology is continuous casting and rolling, which belongs to the series of hot-rolled aluminum plates, so it can be used for deep oxidation processing. In my country, the 5000 series aluminum sheet is one of the more mature aluminum sheet series.

Three. The 6000 series represents 6061 which mainly contains magnesium and silicon. Therefore, the advantages of the 4000 series and 5000 series are concentrated. 6061 is a cold-treated aluminum forging product, suitable for applications with high requirements for corrosion resistance and oxidation. Good workability, excellent interface characteristics, easy coating, and good processability. The general characteristics of 6061: excellent interface characteristics, easy coating, high strength, good workability, and strong corrosion resistance. Typical uses of 6061 aluminum: aircraft parts, camera parts, couplers, ship parts and hardware, electronic parts and connectors, etc. Considering the texture, hardness, elongation, chemical properties and price of the material itself, the 5052 alloy aluminum plate in the 5000 series aluminum material is commonly used for aluminum substrates.

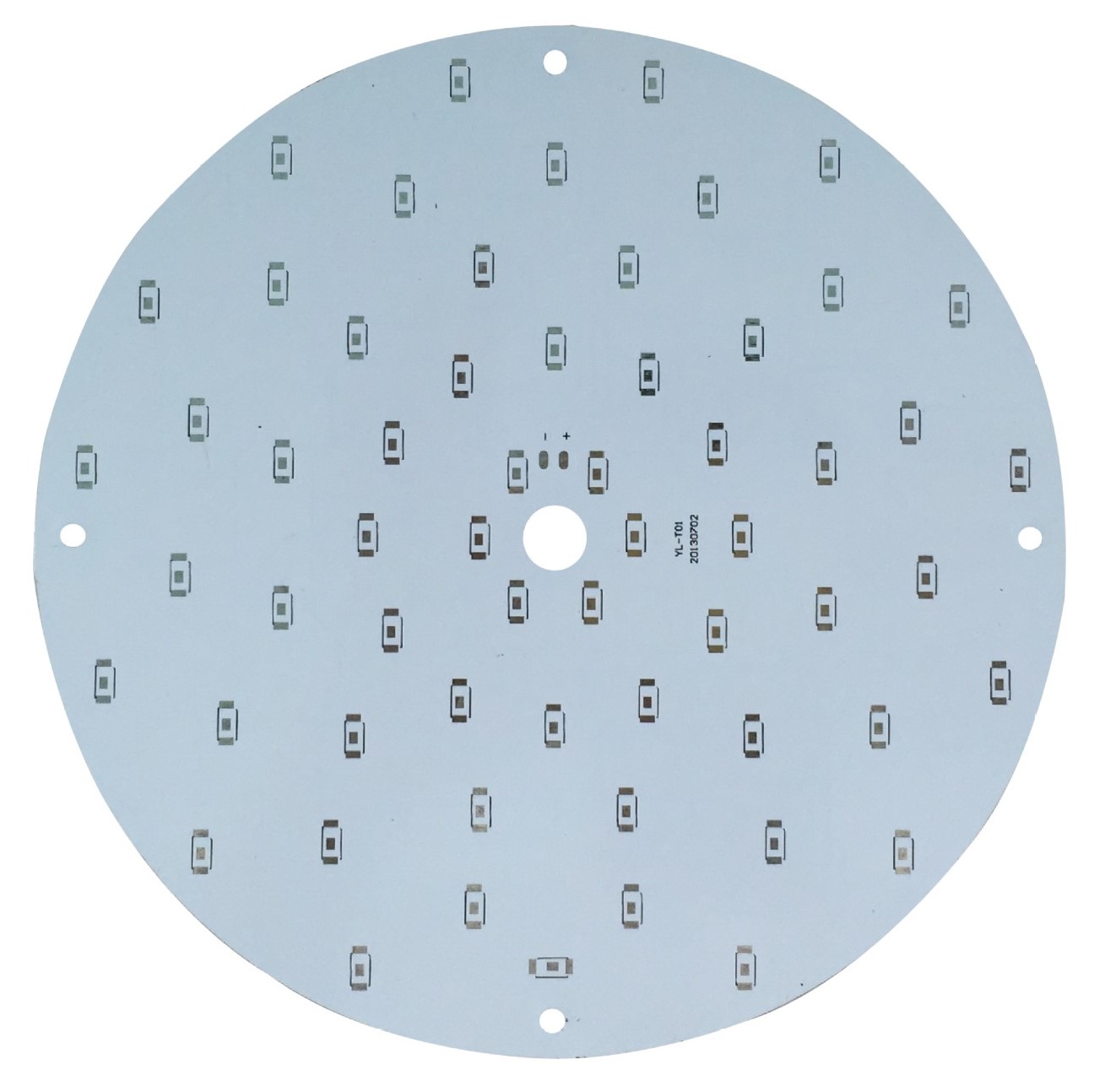

Aluminum substrates can be divided into:

1. The aluminum substrate is sprayed with tin. There are lead-free sprayed tin and lead-free sprayed tin. The cost of lead-free sprayed tin is slightly higher.

2. anti-alumina substrate, namely OPS, environmentally friendly, no tin on the surface, light copper welding.

3.silver-plated aluminum substrate, even if there is no tin, there is no tin exposed on the surface, and the surface of silver is slightly cheaper than immersion gold.

4. Immersion gold aluminum substrate. Immersion gold means that copper, tin, silver, etc. are not allowed on the surface, and the manufacturing cost is relatively high, especially in terms of syrup.

can be divided into: street lamp aluminum substrate, fluorescent lamp aluminum substrate, LB aluminum substrate, COB aluminum substrate, package aluminum substrate, bulb aluminum substrate, power supply aluminum substrate, automobile aluminum substrate, etc.